business

We will respond to your request to solve your tasks made to order.

We will verify and propose according to the cooking environment.

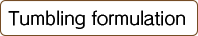

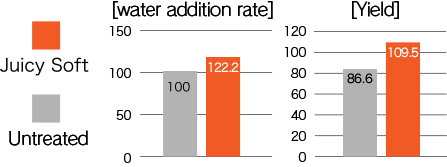

high water adding rate and yield improvement effectmasking effect

- Water and the preparation are dissolved into a paste at a ratio of 1:1.

It is then diluted with the prescribed amount of water to produce a pickle liquid.

The recommended dosage is 1.0%~2.0% to meat.

- Salt / Processed starch, pH adjustment agentAllergen: None

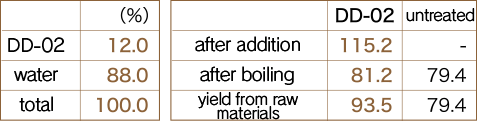

- Roasted pork belly

Raw meat: Pork belly

Process

(1) Stir the formulation with water: pickle liquid

(2) Tumbling with 30% pickle liquid against meat

(3) Refrigerate overnight

(4) Discard excess pickle liquid and weigh it.

(5) Add 30% sauce against the meat and boil at 95°C for 120 minutes.

(6) Remove the heat and refrigerate

※This is based on our test results and the results may vary depending on conditions.

Please test again under real conditions.

Food seasoning made from only salt and sugarCreates a natural softness and juiciness

- The pickle liquid is prepared by dissolving the formulation in water.

The recommended dosage is 1.0% to meat.

- Salt, Sugar

Allergen: None

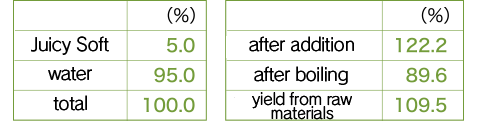

- Fried chicken

Raw meat: Chicken breasts (domestic)

process

(1) Cut into 25 to 35 grams per piece

(2) Dissolve the formulation in water: Pickle liquid

(3) Tumbling with 30% pickle liquid against meat.

(4) Discard excess pickle liquid and weigh it.

(5) Dust the meat with 20% potato starch and fry it twice for 2 minutes and 1 minute at 170℃.

(6) Weighing and food inspection

※This is based on our test results and the results may vary depending on conditions.

Please test again under real conditions.

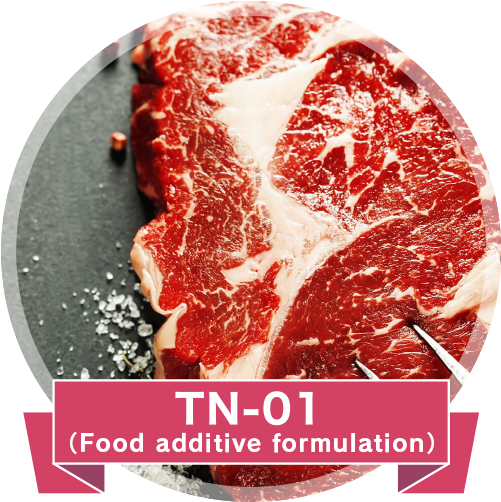

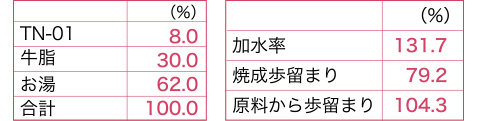

It's fine and evenly marbled.

It gives a natural finish without a processed look.

- Dissolve the formulation in water and emulsify it with fat.

Formulation 8.0%

Oils and fats 30.0%

Water 62.0%.

Recommended pickle liquid addition ratio 30% to 40%

- Salt, Milk protein, Sugar, Dietary fiber, White fungus extract / Processed starch, pH adjuster

Allergen: Milk, Orange

- Steak

Raw meat: Striploin (AUS)

process

(1) Stir the hot water and formulation, add beef fat and emulsify: Pickle liquid

(2) Injection

(3) Freeze after one hour of refrigeration

(4) Cut it into 1 centimeter in thickness

(5) Grilling them on a hot plate (core temperature is 75°C or higher)

(6) Weighing and food inspection

※This is based on our test results and the results may vary depending on conditions.

Please test again under real conditions.

- Beef/Pork/Chicken/Fish

We will respond to your request made to order.

Beef produced at our factory is supplied to local mass retailers and Restaurant chains.

The local staff has spent years finding business partners.

We will also supports your advance into Thai market, foreign trade and other services.

We are carrying out meat processing at our own factory, we supply goods with SNOW BEEF brand to Thai domestic mass retailers and Restuarant chains.

We have been exporting Wagyu beef, F1 beef, food additives related to beef injected with beef tallow mixture, and food processing machinery from Japan to Thailand. Also, we have been importing food ingredients from Thailand to Japan.

・Seasoning export・Machine export・Manufacturing at our own factory・Advance support

We have been exporting food seasonings and food additives developed and manufactured in Japan to China.

We also support export of food processing machinery according to consultation.

We have exported food seasonings developed and manufactured in Japan to China.

They have been introduced in a major restaurant chain. We also support export of food processing machinery according to consultation.

Seasoning export Machine export